For years, Surface-Mount Device (SMD) LED technology has enjoyed a wide adoption as indoor advertising displays. While it’s served its purpose, anyone who's worked with these screens knows their limitations: sometimes they struggle with up-close viewing, offer less robust protection for the tiny LED components, and can be a bit of a headache to maintain.

The truth is, the dynamic world of indoor advertising demands something more, a technology that can truly elevate visual experiences and stand the test of time. Enter Chip-on-Board (COB) LED technology now.

When evaluating display technologies for indoor advertising, several key factors come into play. Here's how COB LED technology stacks up against traditional SMD. Hold on! If you have no time for all the details, the table can help you a lot.

|

COB LED |

SMD LED |

|

|---|---|---|

| Visual Experience | No graininess. Better for prolonged close-up viewing. | Can appear grainy up close due to being a point light source. |

| Contrast and Color | Higher contrast and more vivid colors. | Lower contrast and color vividness compared to COB. |

| IP Rating | Better | Weaker |

| Power Consumption | Lower power consumption | Higher power consumption |

| Beam Angle | Wider | Narrower |

|

Durability |

More durable due to fewer components. | Less durable and more prone to failure due to more components. |

COB technology excels in achieving much finer pixel pitches. Because the chips are directly mounted and tightly packed without bulky bonding wires or individual packages, COB displays can offer significantly higher resolutions and a smoother image even at very close viewing distances. This makes them ideal for environments where viewers are in close proximity to the screen.

The direct encapsulation of LED chips with epoxy resin makes COB displays inherently more robust and resistant to damage. They offer improved protection against moisture, dust (often with an IP54 rating), and physical impact.

SMD displays, with their exposed LED components and soldered connections, are more susceptible to damage from external factors, typically having lower IP ratings (IP20 or IP30). This enhanced durability translates to a longer lifespan and greater reliability for COB screens.

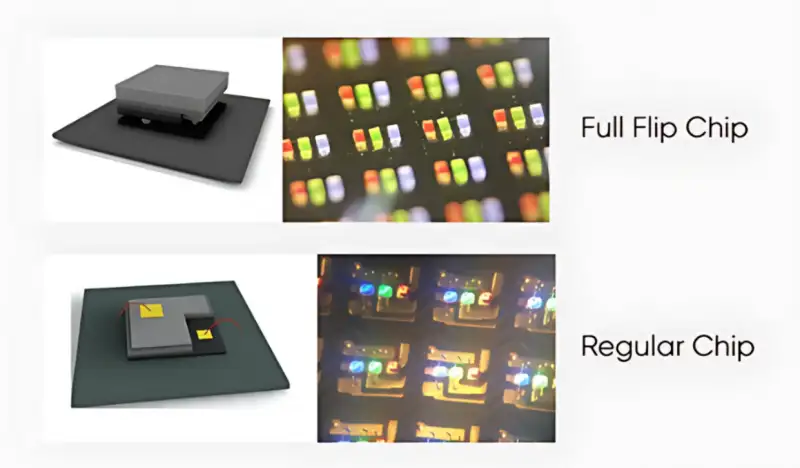

COB LED displays generally offer wider viewing angles, often up to 170 degrees. This is largely due to the "flip-chip" technology used in COB, which minimizes obstructions to light emission.

A wider viewing angle ensures that your content remains clear and vibrant from various positions within a space, maximizing audience engagement.

COB LED technology demonstrates higher energy efficiency compared to SMD. They convert more energy into light and generate less wasted heat, making them more "efficacious." This efficiency leads to lower operational costs over time, especially for large, continuously running displays, contributing to a more sustainable advertising solution.

Thanks to their robust construction and fewer points of failure, COB displays typically require less frequent maintenance. Their durable nature means fewer replacements and less downtime, saving businesses time and resources on upkeep.

While SMD repairs are possible, their greater susceptibility to damage can lead to more frequent and complex maintenance needs.

While the initial manufacturing and purchase cost of COB LED displays might be higher than that of SMD, their long-term cost-effectiveness is a significant advantage.

The superior energy efficiency, extended lifespan, and reduced maintenance requirements of COB technology can lead to substantial savings on operational expenses and replacement costs over the total cost of ownership.

First, let's get to know the structures of the two LED encapsulation methods.

COB LED integrates multiple LED chips directly bonded onto a substrate, typically aluminum or ceramic PCB, with minimal interconnects, forming a unified, high-density light source.

SMD LEDs are small packaged devices soldered on a PCB. Each LED (“lamp bead”) includes its own chip, phosphor, lens, and circuit pads.

|

COB LED

|

SMD LED

|

|

|---|---|---|

| Light Source | Uniform panel/area light | Point source per chip |

| Thermal Path | Chip → substrate → heatsink (short path) | Chip → glue → pad → solder → PCB → heatsink (longer path) |

| Circuit Complexity | One circuit for all chips | Separate circuit per LED |

| Brightness & Uniformity | Excellent; minimal hotspots | Good; depends on LED spacing |

| Color Flexibility | Limited (phosphor white light) | Excellent (RGB tunability) |

| Typical Size | Larger modules for high power | Small packages (mm-scale) |

| Manufacturing | Specialized for high density, lower complexity of wiring | Standard SMT processes |

No hesitation to adopt COB LED display to your indoor advertising or presentation plan. The compelling combination of high visual clarity, durability, and energy efficiency won’t let you down.

Its robust structure, extended lifespan, and silent, low-heat operation ensure reliable performance in demanding settings, while the compact design allows for easy maintenance. These advantages lay the foundation for its growing use in a range of indoor advertising applications:

Now that you've made up your mind on choosing the LED technology, but what to choose? Allow us to introduce the LAMPRO LC COB Series.

The COB LED module features a standard 320mm×160mm size, ultra-light 0.5kg modules, and a slim 12mm profile. The installation and disassembly are incredibly quick and easy, thanks to its magnetic module design.

This series is also superior in the visual performance:

We also know your consideration of lifespan and maintenance, like whether it is durable or fixable, or how tough it is to fix?

Well, YES, YES, and NO!

This series is built for resilience. The LC COB Series features high overall surface protection, making it waterproof, dustproof, anti-static, and anti-bump. And to minimize the failure rate, this series boasts flip COB technology to eliminate traditional welding wires. The design cuts the failure rate by 50% and boosts luminosity by 50% for incredible stability and brightness.

For more information, visit our website or consult us.

Ready to revolutionize your visual communication? Visit LAMPRO today and consult with our experts to discover more LED display innovations tailored for your needs!